Can I Use Normal Printer Ink on Heat Transfer Paper?

Can you use normal printer ink on heat transfer paper? Absolutely, but there are a few things to keep in mind. Normal printer ink is readily available and can be used for DIY heat transfer projects, making it a convenient option for personalizing t-shirts, bags, and other items from home.

While this method may not provide the same longevity or washability as specialized heat transfer inks, it’s a cost-effective and accessible choice for those just starting or doing projects that don’t require professional-grade durability. This approach is particularly great for fun experiments, one-off events, or items that won’t be subjected to heavy wear and tear.

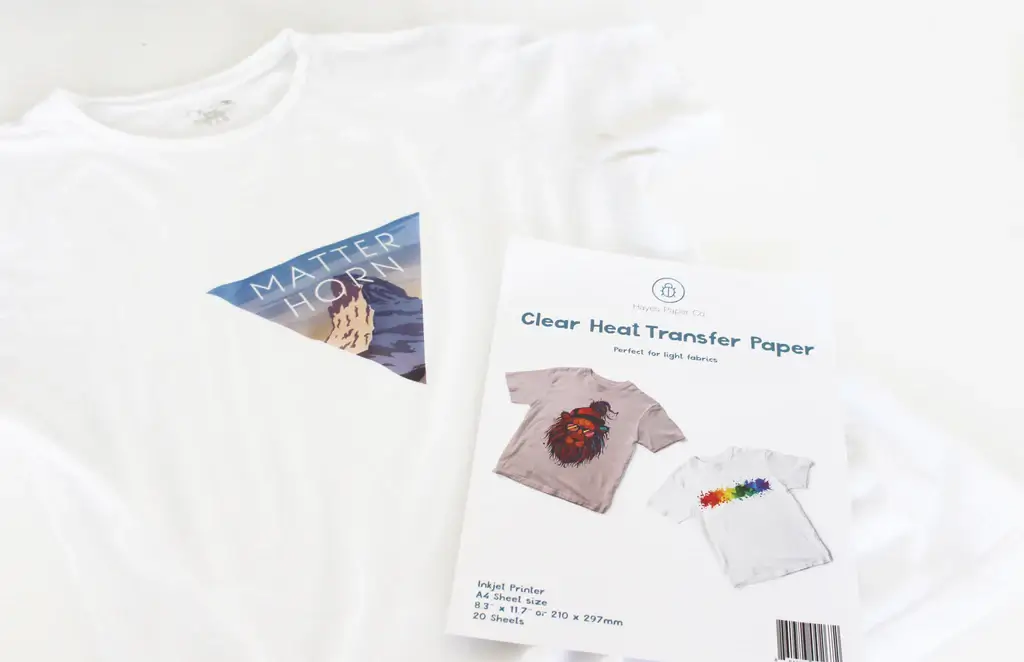

What is Heat Transfer Paper

Heat transfer paper is a special type of paper used to print designs that can then be transferred onto fabric and other materials using heat and pressure. This paper works as a carrier for your printed graphic; when heat is applied, the design is transferred from the paper to your chosen material, such as a t-shirt, canvas bag, or even a mug.

Heat transfer paper comes in two main types: one for use with inkjet printers and another for laser printers, ensuring that you can use whatever printing tools you have at home. This method is popular for creating custom apparel, personalized gifts, and unique home decorations. It’s particularly favored by DIY enthusiasts and crafters looking to put a personal touch on their projects without needing complex equipment.

Why You Can Use Normal Printer Ink on Heat Transfer Paper

Using normal printer ink on heat transfer paper is a feasible option for several reasons, making it a practical choice for certain types of projects. Here are the key factors that support the use of regular printer ink in heat transfer applications:

- Compatibility with Standard Printers

Most households and small businesses already have standard inkjet printers that use normal printer ink. These printers can handle heat transfer paper, making it easy to start a project without the need for specialized printing equipment.

- Specific Heat Transfer Papers

There are varieties of heat transfer papers available that are specifically designed to work well with normal inkjet inks. These papers help ensure that the ink adheres properly and transfers cleanly onto the fabric or other substrates.

- Adequate Heat Transfer Performance

While not as perfect as specialized inks, normal printer inks can still achieve decent results when used on heat transfer paper. For projects that don’t require ink to withstand frequent washing or intense durability, such as decorative items, prototypes, or one-time-use projects, normal ink can suffice.

- Reduced Cost and Accessibility

Using normal printer ink can significantly reduce the costs associated with printing as it eliminates the need to purchase additional, more expensive inks like sublimation or solvent-based varieties. This makes heat transfer projects more accessible to hobbyists and small businesses.

- Ease of Use for Beginners

For those new to heat transfer printing, starting with materials and equipment they already have—like an inkjet printer with normal ink—makes the process less daunting. It provides a gentle introduction to the world of custom printing without the steep learning curve associated with more complex equipment.

- Immediate Availability

Normal printer ink is readily available at most office supply stores or online, making it easy to replenish supplies and continue with projects without delay.

While using normal printer ink for heat transfer doesn’t offer the same level of durability and washability as specialized inks, it holds considerable advantages for casual use, experimentation, and non-commercial projects. This approach allows for creativity and personalization with a lower barrier to entry.

Benefits of Using Specialized Inks

While the use of common printer inks for thermal transfer projects is feasible for temporary or experimental use, there are significant benefits to using specialized inks designed specifically for thermal transfer applications. Below are the key benefits of using specialized inks for thermal transfer printing:

- greater durability: specialized inks are formulated to withstand high temperatures and pressures and are less prone to fading, cracking, and peeling, ensuring a long service life, especially for items that are subjected to frequent use.

- Excellent color quality: Vivid and consistent color quality maintains integrity over time, providing bright, clear designs even under pressure.

- Specialized finishes: Specialized inks produce a glossy appearance, which is essential for maintaining high-quality standards, especially for businesses or individuals selling printed materials.

- Compatible with advanced printing technology: Compatible with advanced machines for high volume and fine designs, ensuring versatility in printing capabilities.

Overall, while normal printer ink can be suitable for simple, non-commercial projects, specialized inks provide a level of performance and quality that is essential for professional results and commercial applications. They ensure that products are not only attractive but also durable and safe for various uses. To find out more, delve into ‘What is an Inkjet Printer?‘ This guide details the types of inkjet printers, their features, and why they can fulfill your printing needs.

Alternative Inks for Heat Transfer Paper

When selecting inks for heat transfer paper, consider these alternative options, each suited for different materials and project requirements:

- Sublimation Ink: Ideal for polyester and polymer-coated items, it bonds directly to the fabric, offering vibrant and durable prints with no texture.

- Pigment-Based Ink: Suitable for cotton and blends, it provides UV-resistant prints that are perfect for long-lasting and outdoor applications.

- Solvent Ink: Used for materials like vinyl, these inks are chemical and abrasion-resistant, making them great for both indoor and outdoor signage.

- Eco-Solvent Ink: Similar to solvent inks but less toxic and suitable for a wide range of substrates, offering safe home use with minimal odor.

- UV Ink: Applicable to soft and rigid substrates, it cures instantly under UV light to produce scratch-resistant and weatherproof prints.

- Latex Ink: Compatible with various textiles and synthetics, it’s eco-friendly, odorless, and provides good outdoor durability without lamination.

These alternatives offer diverse benefits tailored to specific durability, quality, and environmental considerations.

Considerations When Using Normal Printer Ink

While using normal printer ink on heat transfer paper can be feasible for certain projects, there are important considerations to keep in mind to ensure the best possible outcome:

Durability and Longevity

Regular printer ink is not formulated for high durability under heat and washing. Printed designs may fade or degrade quickly with regular use and washing, making them less suitable for items that require long-term wear or exposure.

Quality of Transfer

The vibrancy and clarity of the transfer may not match those achieved with specialized heat transfer inks. Normal ink might bleed or appear dull once transferred, particularly on fabrics.

Material Compatibility

Normal printer inks are primarily designed for paper and may not perform well on other materials without the proper coating. It’s crucial to select heat transfer paper that is compatible with regular inkjet inks to avoid issues like poor ink adhesion.

Heat Sensitivity

Regular inks may not be as resistant to heat as specialized inks. This can lead to issues during the transfer process, such as uneven transfer, smudging, or even damaging the material being printed on.

Washability

Items created with regular printer ink on heat transfer paper may not withstand washing well. Ink can wash out or degrade, which is problematic for clothing and fabric items.

Economic Considerations

Although initially cheaper, using regular printer ink can lead to higher costs over time due to the need for frequent replacements or reprints due to lower quality and durability.

Printer Wear and Tear

Using heat transfer paper in a regular inkjet printer designed for paper printing can potentially lead to increased wear and tear on the printer. It’s important to consider the impact on your equipment before undertaking large or frequent heat transfer projects.

Conclusion

Using regular printer ink on thermal transfer paper offers a convenient and accessible option for DIY projects, especially for beginners or one-time attempts. While it may lack the durability and professional results of specialized inks, it’s still a great option for temporary use, experimentation, and non-commercial purposes. For projects that require durability and quality, specialized inks offer superior performance and are the key to professional results.

For all your printing needs, whether it’s for DIY heat transfer projects or professional tasks, YB Toner is your go-to destination. We specialize in providing high-quality Brother toner and other printing supplies that ensure optimal performance and stunning print quality. Don’t let subpar print materials hold you back. Visit YB Toner today to find the best in Brother ink and toner for your next project.